By: Marc Schwartz, President of Ozone IT Services.

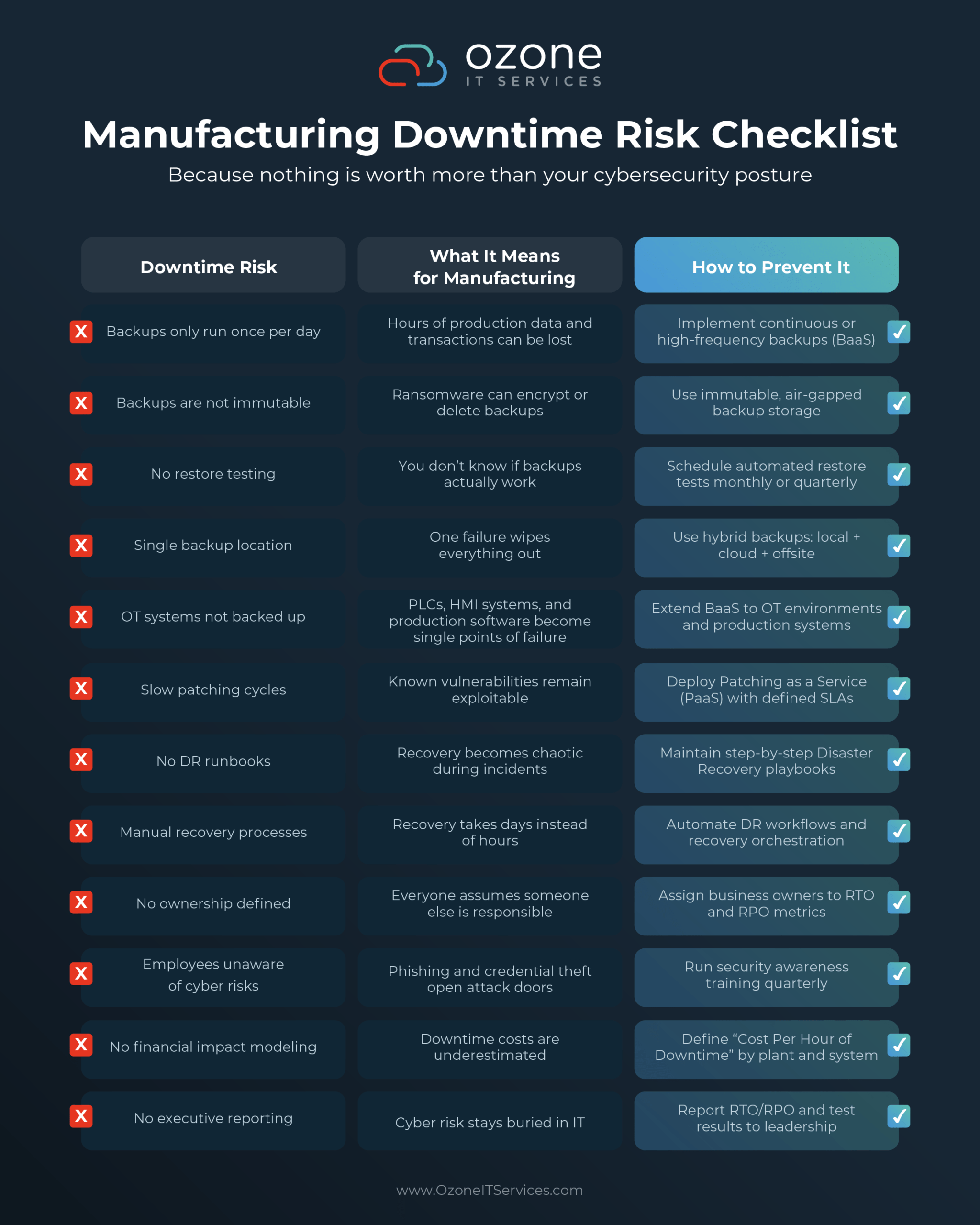

The checklist below helps IT and business leaders see cybersecurity through a business lens. It connects technical gaps directly to production loss, revenue exposure, and operational disruption, making risk measurable instead of abstract. When leaders understand how backups, patching, disaster recovery, and ownership tie to financial impact, cybersecurity shifts from a defensive cost to a strategic control over uptime, profitability, and customer trust.

Interpreting the Quadrants Through a Manufacturing Lens

Downtime is not an IT problem. It is a revenue, reputation, and operational continuity problem. Backup-as-a-Service (BaaS), Patching-as-a-Service (PaaS), and hybrid infrastructure transform downtime risk from guesswork into controlled, measurable protection. For more information, visit OzoneITServices.com.

Marc Schwartz is the President of Ozone IT Services and brings over 30 years of experience designing and securing IT infrastructure, with deep specialization in Backup as a Service (BaaS), Patching as a Service (PaaS), and cybersecurity for manufacturing environments. Known for his ability to eliminate the chaos of ransomware and cyber disruptions, Marc helps manufacturers stay secure, operational, and profitable by solving problems before they happen and building systems that keep businesses running when it matters most.

Resilience Ready

Learn how Ozone and Veeam together can strengthen your recovery posture, reduce downtime risk, and protect your operations with a resilience readiness assessment.

Contact Us.